Planning a new construction project is a big move. Let’s be honest here. The math can be a total headache. You want to know the actual concrete slab cost without getting hit by hidden fees. In 2026, you can expect to pay between $6.50 and $13.00 for the concrete slab cost per square foot. For a standard residential project, the average price often sits right around $8.75 per foot. Look, if you’re planning a 20×20 concrete slab cost budget, your total will likely land between $3,200 and $5,600. It really just depends on your specific site and what you are parking on top of it.

This guide provides a deep dive into the numbers. We’ll look at everything from the 3000 PSI mix price to those pesky labor finishing charges. You will see exactly why one quote is higher than another. Most importantly, you will learn to plan like a professional.

Factors Affecting Concrete Slab Pricing in 2026

You might think concrete is just gray mud. It’s not. There is a lot going on under the surface. Several things change your final bill. The biggest one? Usually, it’s the site preparation expenses. If your yard isn’t level, you’ll pay more. If you have old tree roots or massive rocks in the way, you’ll pay even more. Digging and grading take time. Time is money.

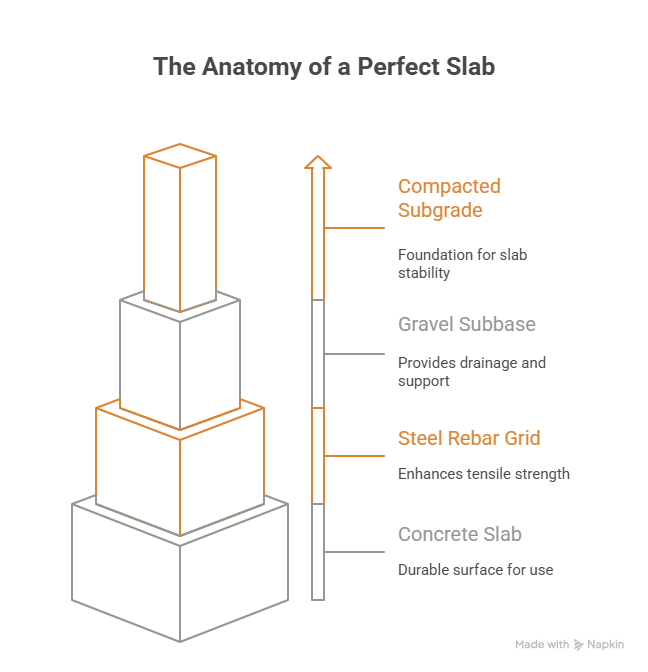

Next is the subgrade compaction. You can’t just dump concrete on loose dirt. It will sink. It will crack. A pro will use a heavy plate compactor to pack the ground tight. Then they add a gravel base layer. This stone layer is usually 4 inches deep. It lets water drain away. It also stops the slab from moving during a freeze. Trust me, these are the factors affecting concrete slab pricing that most people forget. If you pour on “virgin” soil that hasn’t been packed, your slab will settle. When it settles, it breaks.

You also have to budget for the formwork setup fees. This is the cost of building that wooden frame. It keeps the wet concrete in place. If your slab has a “thickened edge” for a garage foundation, those forms take more time. They need more lumber. They need more stakes. It is more than just four boards in a square.

How Much Concrete for 20×20 Slab 4 Inches Thick?

A 20×20 area covers exactly 400 square feet. It’s the gold standard for many backyard builds. To get your materials right, you need an accurate cubic yards calculation.

For a 4 inch concrete slab thickness, the math says you need 4.93 cubic yards. If you want a 6 inch thickness for a driveway, you need 7.41 cubic yards.

Here is the thing. Never order the exact number the math gives you. Ever. The ground is never perfectly flat. Forms will move slightly. You should always add a 10 percent waste factor. This means you should order 5.5 yards for a 4 inch slab. If you run out of concrete while the truck is there, you’ll pay a massive “short load fee.” It is much cheaper to have a half yard left over than to be a half yard short. Running out of concrete is the fastest way to ruin your day. Use our concrete slab cost calculator to be sure.

2026 Pricing Table by Slab Size

Small slabs, like a shed foundation slab cost calculator estimate, often have a higher price per foot. Why? Minimum delivery fees. Most concrete companies have a “minimum” order. If you only need two yards, they might charge you for five. Here is a residential slab foundation cost breakdown for common sizes.

| Slab Size | Total Square Feet | Est. Professional Cost (4″) | Est. DIY Material Cost |

| 10×10 | 100 sq ft | $950 – $1,600 | $450 – $600 |

| 12×12 | 144 sq ft | $1,250 – $2,100 | $600 – $850 |

| 16×20 | 320 sq ft | $2,700 – $4,200 | $1,200 – $1,600 |

| 20×20 | 400 sq ft | $3,400 – $5,600 | $1,500 – $2,100 |

| 24×24 | 576 sq ft | $4,800 – $7,800 | $2,200 – $3,000 |

| 30×30 | 900 sq ft | $7,500 – $11,500 | $3,400 – $4,800 |

| 40×60 | 2,400 sq ft | $18,000 – $28,000 | $9,000 – $12,000 |

Planning to build a brick structure on your new slab? Once your foundation cost is set, you can find the exact material count for your walls using our Brick Calculator. It is the fastest way to budget for masonry and mortar bags in one step.

The Science of Soil: Why Your Base Matters

Most people think the concrete is the foundation. It isn’t. The soil is the foundation. If you live in an area with “expansive clay,” your soil grows when it gets wet. Then it shrinks when it gets dry. This movement is what kills concrete.

To fight this, you need a solid gravel base layer. The gravel acts as a “buffer” between the moving dirt and your stiff slab. If your contractor says you don’t need gravel, they are wrong. Unless you are pouring on top of solid rock, you need a subbase. This prep work is where the best contractors spend most of their time. It is the difference between a slab that lasts five years and one that lasts fifty.

Concrete Mixes and PSI Strength

When you call the concrete plant, they will ask what PSI you want. This stands for pounds per square inch. It is a measure of how much weight the concrete can handle.

For a 20×20 patio, a 3000 PSI mix price is your baseline. It is strong enough for foot traffic and patio furniture. But if you are building a driveway, you should step up to 4000 PSI. It handles the weight of heavy SUVs better. In 2026, the price difference is usually only about $10 per yard. It is a small price to pay for a much stronger floor.

Some plants also offer “air-entrainment.” These are tiny bubbles mixed into the mud. They give the concrete space to expand when water inside it freezes. If you live in a cold climate, you must have this. Without it, the surface of your slab will start flaking off in just a couple of winters.

Labor and Finishing Charges

Labor is often the biggest part of your bill. You are paying for the skill of the finishers. They aren’t just dumping mud. They have to “screed” it, which means leveling it with a long board. Then they “bull float” it to push down the rocks and bring the “cream” to the top.

A standard broom finish is the cheapest. It gives you a non-slip surface. If you want a smooth “trowel” finish for a garage, it takes more time. The finishers have to wait for the concrete to start setting before they can get on it with power trowels. This waiting time increases your labor finishing charges.

If your site is hard to reach, you might need a concrete pump rental. This is a truck with a long boom arm. It can pump the concrete over a house or through a narrow gate. It usually costs between $650 and $950 for a half day. It saves your back but it adds a lot to the budget.

Reinforcement: Wire Mesh vs Rebar

Steel is what gives concrete its “tensile” strength. This means it can bend slightly without snapping. Wire mesh vs rebar is a common choice for homeowners.

Wire mesh is a grid of thin steel wires. It is easy to lay down. It works well for thin 4 inch slabs. But it often ends up at the bottom of the pour where it does nothing. Rebar is much stronger. It is made of thick steel rods. For a garage concrete slab thickness and price plan, rebar is the only way to go.

Adding steel increases your rebar reinforcement cost. It adds about $1.00 per square foot. In 2026, steel prices have stayed high. But don’t skip it. A slab without steel is just a collection of cracks waiting to happen.

Regional Cost Comparisons: 2026 Data

Concrete prices are local. You can’t ship a truck across the country. In the United States, concrete prices per yard delivered 2026 average around $187.

In Canada, prices are usually calculated in cubic meters. You can expect to pay between $225 and $285 CAD per cubic meter. Because of the cold, Canadian slabs often require extra work. Deep frost lines are no joke. If the ground freezes and thaws, a slab without a deep gravel base layer will snap.

In the UK, the market is slightly different. Ready-mix concrete usually costs between £115 and £155 per cubic meter. You also have to factor in a 20 percent VAT. That adds a big chunk to the bill. Ground prep in the UK often involves dealing with heavy clay soil. This might increase the stone you need for your subbase.

| Region | Concrete Material Cost (Per Yard/M3) | Labor Rate (Per Sq Ft) |

| USA (National Avg) | $187 per yard | $4.50 – $8.50 USD |

| Canada (Toronto) | $245 CAD per m3 | $7.00 – $13.00 CAD |

| United Kingdom | £140 per m3 | £5.50 – £9.50 GBP |

| Australia | $230 AUD per m3 | $65 – $110 AUD |

DIY vs Pro Concrete Slab Cost Comparison

It is tempting to pour your own slab to save money. You can cut your costs by roughly 50 percent because you do not pay for the professional crew. The DIY concrete slab cost for a 20×20 area usually falls between $1,500 and $2,100. This covers the concrete delivery, gravel, rebar, and tool rentals like a plate compactor.

But be extremely careful. Concrete is permanent and unforgiving. You only get one chance to get it right. Once that truck starts pouring, the clock is ticking. You have about ninety minutes to get the concrete leveled and smoothed before it starts to set. This is the 90 minute rule that professional crews live by. If you do not have a crew of at least three strong people, the concrete will get hard before you finish.

The Impact of Admixtures

Plants can add chemicals to your concrete to change how it behaves. These are called “admixtures.”

- Accelerators: These make the concrete set faster. They are great for winter pours.

- Retarders: These slow down the set time. You need these on hot summer days so the concrete doesn’t get hard before you can finish it.

- Plasticizers: These make the concrete flow better without adding extra water. Too much water makes concrete weak. Plasticizers let you pour a “runny” mix that stays strong.

Each additive adds about $5 to $15 per yard. Talk to your contractor about what your specific job needs.

Seasonal Pouring and the 2026 Forecast

The weather is your boss when you pour concrete.

In the summer, the heat can dry out the surface too fast. This causes “plastic shrinkage cracks.” These look like tiny spiderwebs. They don’t hurt the structure but they look ugly.

In the winter, you have to worry about freezing. If the water in the concrete freezes before it sets, the slab is ruined. You might pay winter concrete slab pouring surcharges for hot water and heaters.

The forecast for 2026 shows that labor will stay the biggest challenge. Finding good finishers is hard. If you find a good crew, book them early. Prices for cement are expected to rise by about 3 percent this year.

Concrete Maintenance: How to Make it Last

Once your slab is poured, your job isn’t done. You need to protect it. Concrete is like a giant sponge. It has tiny pores that soak up water. When that water freezes, it expands. This causes “spalling.” That is when the top layer of your concrete starts flaking off.

To prevent this, you should apply a high-quality sealant. Wait at least 28 days for the concrete to fully cure. Then, apply a penetrating sealer. This keeps water out but lets the concrete “breathe.” You should redo this every three to five years. It costs about $100 for a 20×20 slab. It is a small price to pay to avoid a massive replacement bill.

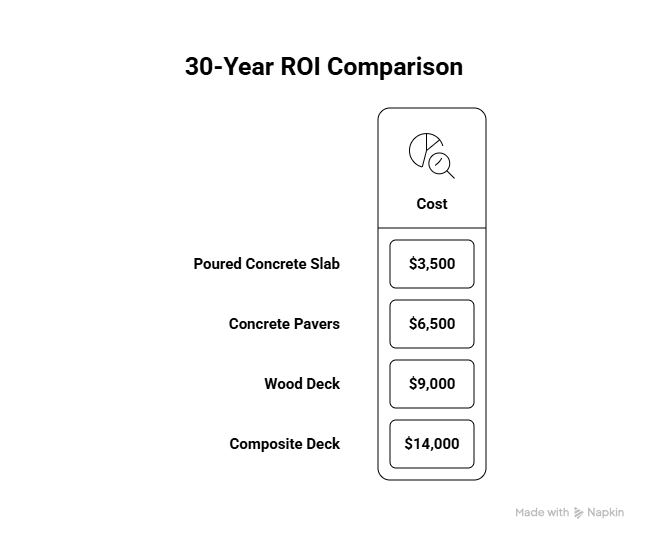

ROI: Concrete vs Decks and Pavers

When you choose a material, think about the long term. A wood deck might look nice now. But it rots. It needs stain every two years. Eventually, the wood fails. Then you have to replace it. It’s expensive and annoying.

Concrete is different. A well poured slab has a massive return on investment. It doesn’t grow weeds like pavers do. It doesn’t attract termites like wood does. It is a “set it and forget it” solution. Over thirty years, a concrete slab is the most cost-effective flooring for any outdoor space. It adds real value to your home. Appraisers love concrete because it is permanent.

Concrete Troubleshooting: What to Do if it Cracks

Cracks are part of life with concrete. There is a saying in the trade. There are two types of concrete. Concrete that is cracked and concrete that hasn’t cracked yet.

Small “hairline” cracks are usually fine. They are caused by the concrete shrinking as it dries. Large cracks are a problem. They are caused by the ground moving. If you see a crack that is wider than a quarter, you should have a pro look at it. You can fill small cracks with a flexible sealant to keep water out.

The Curing Process: The Most Important Week

The first seven days after you pour are critical. This is called the “curing” period. Concrete doesn’t “dry.” It goes through a chemical reaction. This reaction needs water.

If your slab gets too dry too fast, it will be weak. You should keep your new slab wet. Spray it with a hose a few times a day. Or cover it with a plastic sheet to trap the moisture. This simple step can double the strength of your floor. Don’t skip it just because you are tired from the pour.

Understanding Finish Types

Your final surface can look many different ways.

- Broom Finish: The standard. It is rough so you don’t slip when it’s wet.

- Float Finish: A bit smoother than broom. Good for sheds.

- Trowel Finish: Very smooth. Best for indoor garages. It can be slippery when wet.

- Stamped Finish: Made to look like brick or stone. This is the most expensive.

Each finish has its own cost and its own look. Think about how you will use the space before you choose.

Garage Concrete Slab Cost and Requirements

Building a garage is different than pouring a backyard patio. A garage concrete slab cost is usually higher because the requirements for strength and moisture control are much stricter. You aren’t just walking on this surface; you are parking several tons of machinery on it. Once your slab is poured, finish the edges with a clean garden bed. Use our Mulch Calculator to find out exactly how many bags you need for the perimeter.

For a standard garage, you must use a 6-inch concrete slab thickness. While a 4-inch slab is fine for a shed, it will likely crack under the weight of a heavy truck or SUV. You also need to pay close attention to the concrete PSI strength. Most builders won’t go below 4000 PSI for a garage floor to ensure it can handle the pressure and resist salt damage from tires in the winters.

Frequently Asked Question

Final Summary Checklist

Before you pour your slab, check these five things:

- Soil: Is it packed down as tight as possible?

- Base: Do you have 4 inches of gravel?

- Forms: Are the boards straight and level? Use a string line.

- Truck: Is there a clear path for the concrete truck to drive up?

- Help: Do you have at least two strong friends to help you screed?

Planning a construction project? Make sure to manage your finances first. Use our debt payoff calculator to eliminate credit card debt before taking on major home improvement expenses.

Final Pro Tip for 2026 Pours

Don’t just pick the lowest bid. Ask about the concrete PSI strength they plan to use. If they are not using a gravel base layer, they are taking shortcuts. A good contractor will explain the curing time impact. They’ll tell you exactly when you can drive your car on the new floor. They should also talk about sealants. If they don’t, ask them.

Use our concrete slab cost calculator to run your own numbers before you call for quotes. Knowing the yardage ahead of time stops people from overcharging you for materials. Be smart, pack your subbase tight, and your slab will be a solid part of your home for a lifetime. Concrete isn’t just a surface. It is the ground you stand on. Build it right.